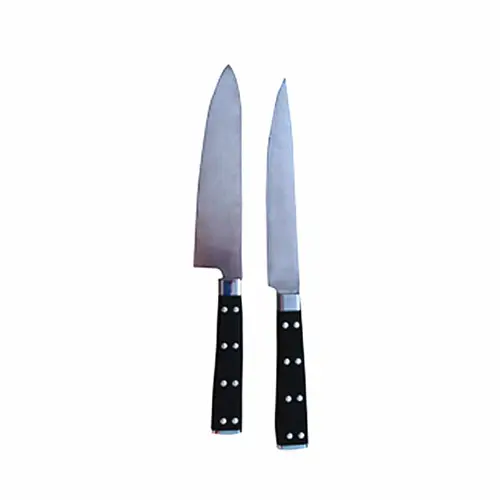

Vowin Rapid Prototyping trader Knife Prototype Services low cost for b2b

The product has good electromagnetic compatibility. It has an adequate level of intrinsic immunity to electromagnetic disturbance to enable it to operate as intended. It can form parts with complex shapes.

Knife prototyping and production is the meticulous process of transforming a mere concept into a tangible, functional tool. It involves the careful design and creation of knife prototypes that undergo thorough testing to ensure their performance meets the highest standards. The journey starts with intensive research and development, where skilled craftsmen employ cutting-edge technologies to bring innovative ideas to life. Through precise engineering and material selection, these prototypes are created with utmost precision, paying close attention to every intricate detail – from blade shape and handle ergonomics to weight distribution and balance. This Knife prototyping and production stage demands an unwavering commitment to quality as each prototype is rigorously tested for durability, sharpness retention, corrosion resistance, and overall functionality. Once approved through rigorous evaluation processes, the prototypes move forward into production where they are meticulously crafted by experienced artisans who possess unmatched expertise in this specialized craft. Across various stages of manufacturing - including forging or stock removal methods - stringent quality control measures are implemented at every step to guarantee consistency in both appearance and performance. From tempering blades for optimal hardness levels to carefully shaping handles with exquisite materials like wood or composite materials; every aspect embodies dedication towards producing knives that exemplify excellence in craftsmanship. Assembled meticulously by hand using traditional techniques combined with modern machinery assistance ensures accuracy while maintaining the essence of true artisanal workmanship throughout production. Ultimately, this complex interplay between creativity, technical proficiency, innovation-driven design philosophy along with an unwavering dedication towards superior craftsmanship results in exceptional knives that meet even the most discerning demands of professionals.Want to know rapid prototyping services cost? Contact us, Vowin provides professional prototyping services for 15 years.

| Port: | Shanghai, China |

|---|---|

| Purchase Qty./Reference FOB Price: | 100 - 999 Pieces $0.05~1.0/piece |

| MOQ: | 10 Pieces |

| Supply Ability: | 10,000,000 PCS/month |

| Application: | Automatic machine, Medical device, industrial machine, Electrical etc |

| Payment: | T/T, Western Union, Paypal, Money Gram |

| Production Type: | Batch Production |

SKYPE: (live:6cc546feac157f61_1)

Wechat: Fennel-Bistro

Address: 201 Room,Building B, Wanli Ye Tech. Park, Chongqing Road, Fuyong Town, Bao'an District, Shen Zhen, China 51810

Contact Sales at Vowin.