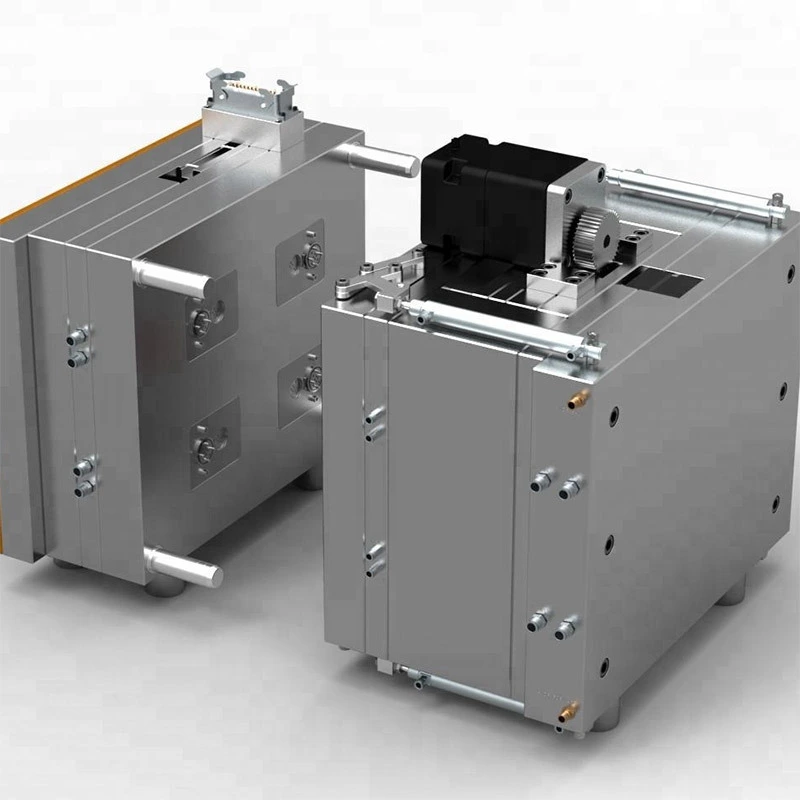

Plastic Injection Mold for industrial machine

Describe

➤ Difficulty in mold opening: Some structural designs have fulfilled the functional requirements, and prototype tests have also been done. When preparing for mold opening, it was discovered that partial mold opening was difficult, and the structure had to be changed again, which extended the development cycle

➤ Increase the complexity of the mold: the mold structure becomes more complex, which means that the cost of the mold increases. A reasonable structure design can simplify the mold structure, thereby reducing the mold cost and increasing the mold life.

➤ Increasing the cost of mass production: injection molding materials with the same structure and different sizes will get different physical properties. A good knowledge of the physical properties of the material can give the best product parameters (wall thickness size, matching position size) during design to avoid causing Unnecessary material waste.

Commonly used injection materials: ABS PP PE PC PA POM PBT PMMA

Product Display

After years of development and innovation, it has developed into a large enterprise integrating R & D, design and production of plates.

Production Process

After years of development and innovation, it has developed into a large enterprise integrating R & D, design and production of plates.

FAQs

How to place the order?

1.You send us drawing or sample;

2.We make the sample and send the picture or video to you for reference;

3.You think the sample is good then place an order and pay us deposit;

How to place the order?

4.We start to make the product;

5.We send the picture or video to you before shipping,then pay the balance;

6.We deliver the products to courier company.

SKYPE: (live:6cc546feac157f61_1)

Wechat: Fennel-Bistro

Address: 201 Room,Building B, Wanli Ye Tech. Park, Chongqing Road, Fuyong Town, Bao'an District, Shen Zhen, China 51810

Contact Sales at Vowin.